PA66GF25 Polyamide thermal barrier strip production line

The PA66GF25 Plastic Extrusion Machine is a cutting-edge automatic PA profile extruder, specially designed for the mass production of aluminum door and window polyamide (PA66GF25) insulation profiles. This advanced extrusion system focuses on the core energy-saving needs of doors and windows, efficiently blocking cold and hot conduction through high-performance PA66GF25 insulation profiles, helping end users reduce energy loss and achieve green energy-saving goals.

Specification

Specification

| Product Name | PA66GF25 Polyamide thermal barrier strip production line |

| Suitable materials | PA66GF25, Nylon 66+25% Glass Fiber, Modified Polyamide, etc. |

| Product Usage | The PA66GF25 nylon thermal barrier strip extruder is compatible with materials like PA66GF25, nylon 66+25% glass fiber and modified polyamide. It can be widely used in multiple fields—it can produce thermal barrier strips for building doors and windows, process energy-saving ones for curtain wall projects, manufacture sealed thermal barrier strips for industrial equipment, and produce lightweight thermal insulation components for the automotive industry, meeting professional processing needs of different scenarios. |

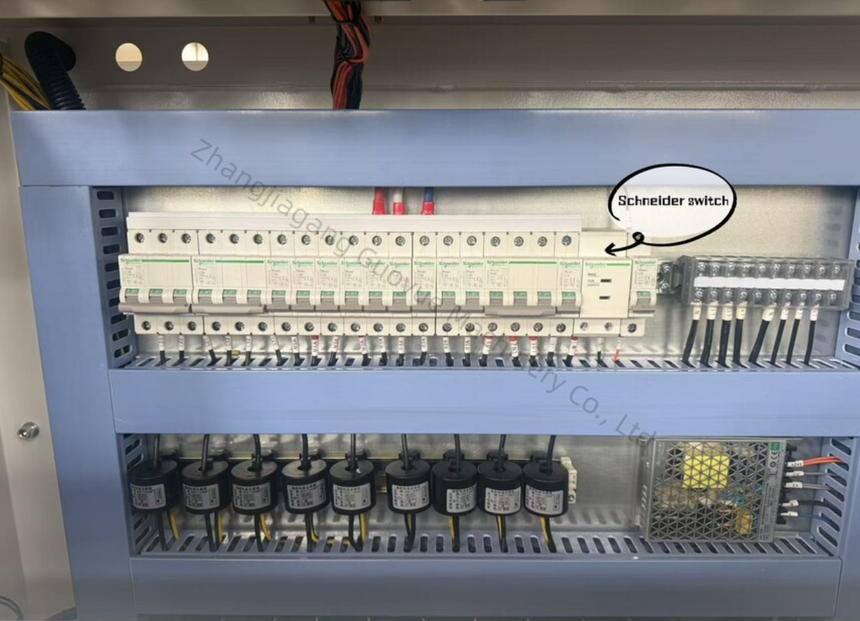

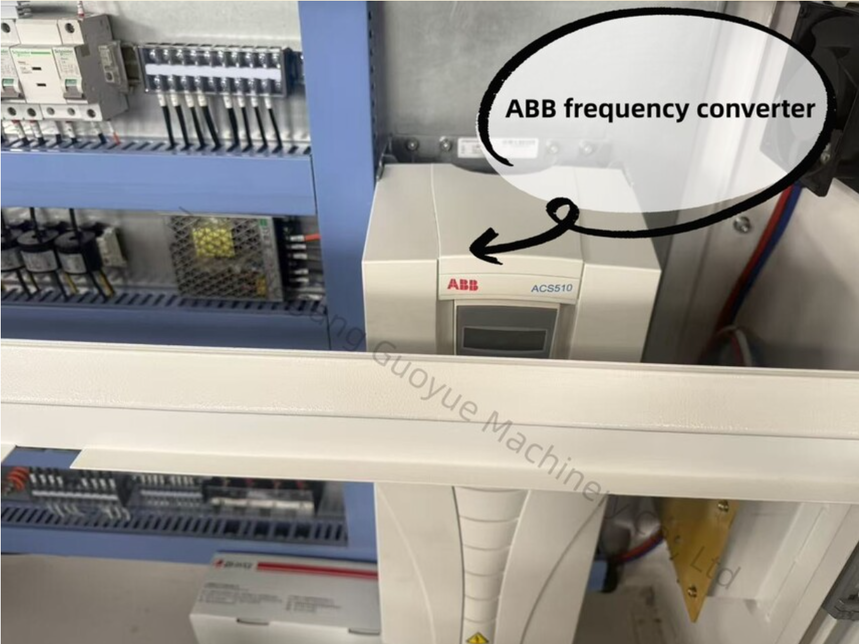

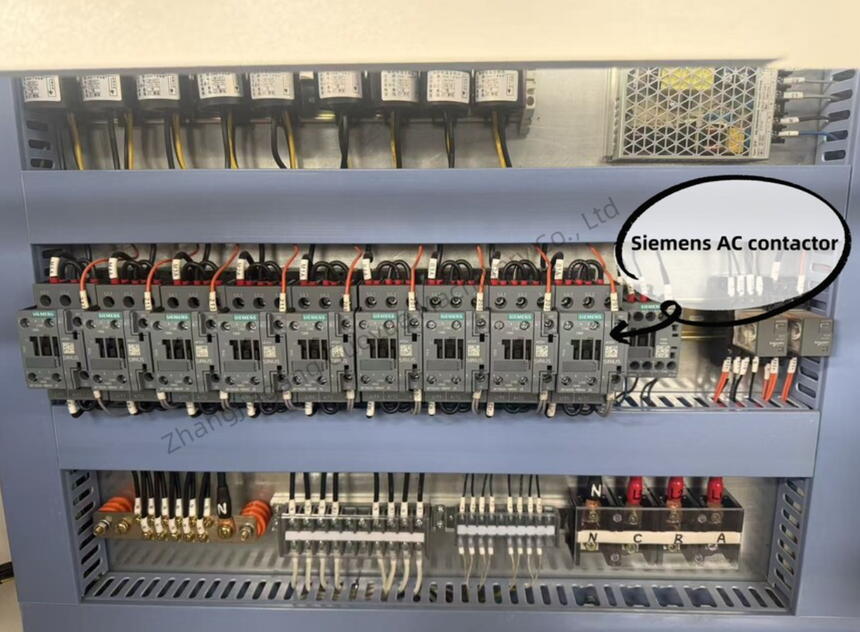

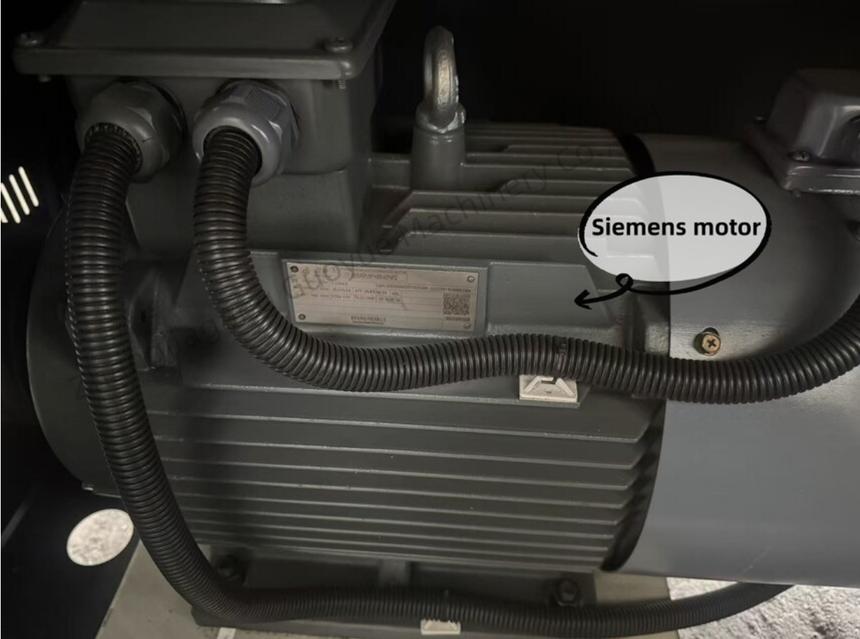

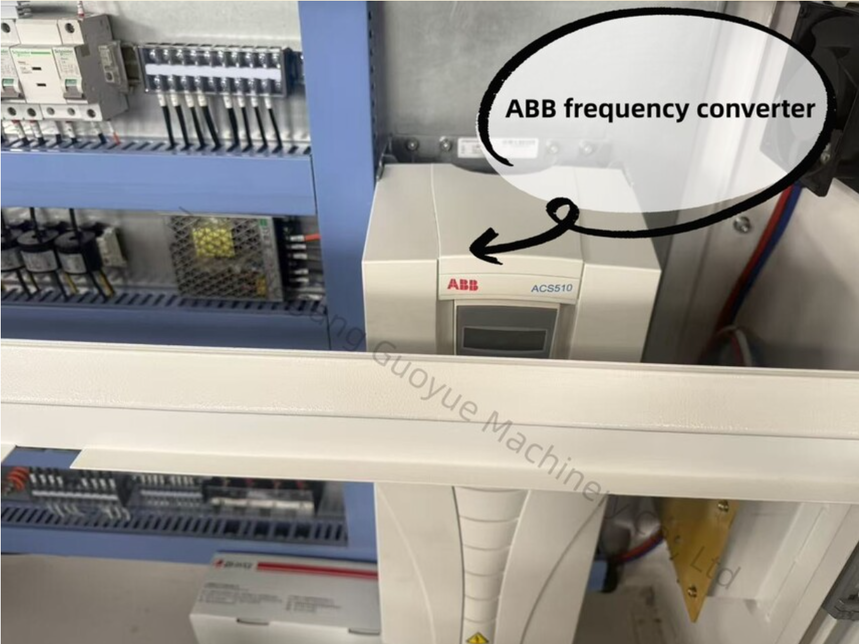

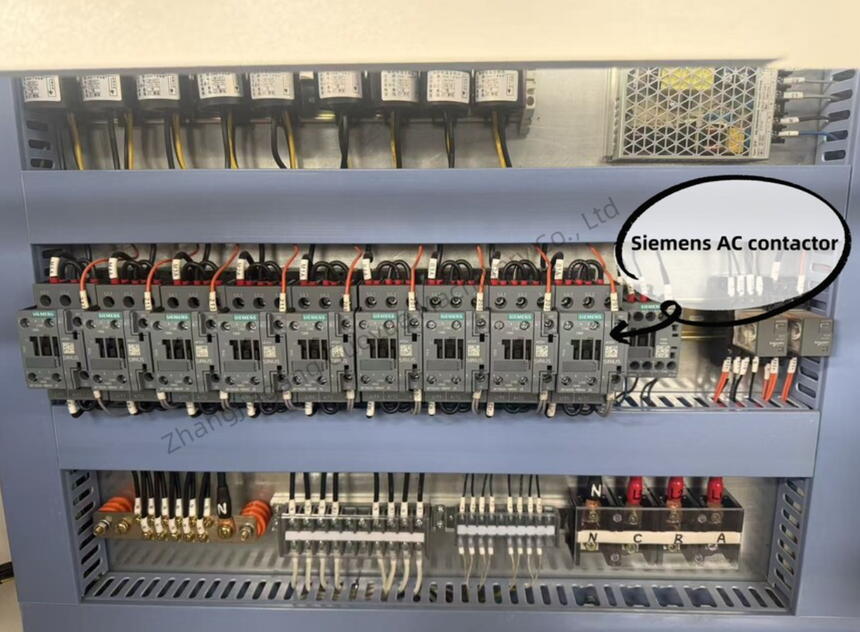

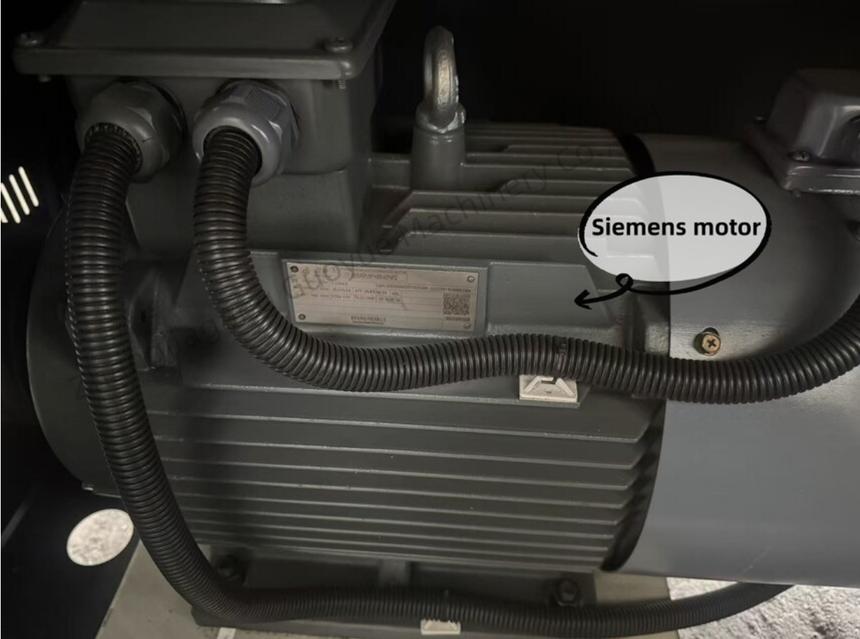

| 1.A high-quality refined hard bimetallic screw is adopted, optimized and designed for the characteristics of PA66+GF25 glass fiber reinforced raw materials. It boasts excellent wear and corrosion resistance, ensuring sufficient and uniform plasticization of raw materials to lay a solid foundation for the high quality of finished products. The main machine is equipped with an energy-saving drive system, reducing energy consumption by 15% compared with traditional equipment, while the rotational speed fluctuation is ≤ ±0.5r/min, ensuring stable and reliable operation speed. |

| 2.The professional hot air circulation dryer adopts a forced convection design, enabling full and uniform contact between PA66+GF25 raw materials and hot air. With a drying uniformity error of ≤2%, it stably reduces the raw material moisture content to below 0.2%, fundamentally avoiding defects such as bubbles and cracks in extruded finished products. Equipped with a high-density thermal insulation structure, the dryer significantly minimizes heat loss, saving 30% more energy than traditional models while balancing drying efficiency and operational economy. |

| 3.The mold is crafted with advanced Japanese molding technology, featuring a short, smooth flow channel free of stagnant dead corners. This enables the rapid and uniform flow of PA66+GF25 raw materials; the finished thermal insulation strips boast a smooth, flawless surface, precise dimensional tolerance control, and excellent mechanical strength, fully meeting the assembly and application requirements of high-end aluminum doors and windows. |

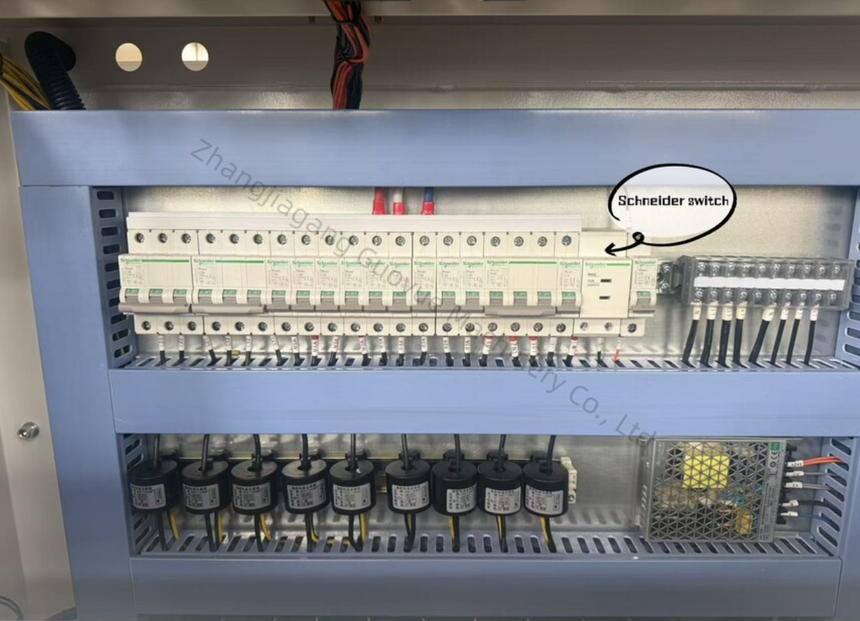

| 4.Genuine Omron temperature controllers are adopted, featuring an independent "one instrument per temperature control zone" design. The temperature control accuracy is stably maintained at ±1ºC, ensuring constant temperature during the plasticization of PA66+GF25 raw materials and avoiding local overheating or insufficient plasticization. |

| 5.The screw heater adopts high-quality ceramic heating elements combined with a high-density thermal insulation layer, delivering excellent heat retention performance. It is compatible with 400V industrial voltage and operates stably and reliably. Compared with traditional metal heaters, it reduces energy consumption by 10% while enabling fast and uniform temperature rise, which can accurately maintain the constant temperature of each section of the barrel, providing stable temperature control support for the full plasticization of PA66+GF25 raw materials. |

Packing & Delivery

The goods are packaged in plywood boxes, which have a sturdy structure and are suitable for transporting and storing large items.

The goods are packaged in plywood boxes, which have a sturdy structure and are suitable for transporting and storing large items.

Company Profile

| Zhangjiagang Guoyue Machinery Co., Ltd |

Our company is located in Zhangjiagang City, Jiangsu Province, China, covering an area of 1,580 square meters and adjacent to the scenic Chanjiang River. We are close to China's only inland river free trade zone, with convenient driving access to key economic hubs such as Shanghai, Suzhou, Wuxi, Changzhou, Nantong and Nanjing.

Leveraging superior geographical location, mature industrial environment, convenient modern communications and developed land-water transportation networks, we have been deeply engaged in the R&D and manufacturing of PA66GF25 thermal insulation strip extruders, supporting molds, as well as related plastic pellets and thermal insulation strips since 2010.

As a professional manufacturer of PA66 thermal insulation strip extruder production lines and molds, we have accumulated rich industry experience and are willing to share it. We can customize molds according to customers' personalized needs and provide a full set of technical support and services.

"Customer-centric and dedicated service" is our core principle adhered to for ten years. We are always committed to providing customers with high-quality products and efficient services. Currently, our domestic sales volume maintains steady growth, and we are actively exploring overseas markets. We plan to promote our products globally and work with customers at home and abroad to achieve win-win cooperation and common development.

|

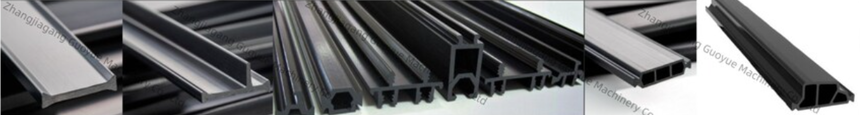

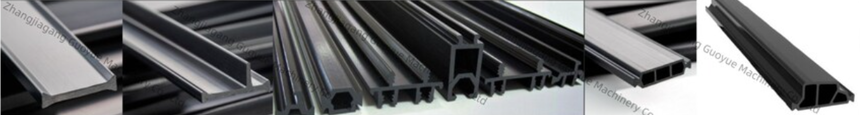

PA66GF25 polyamide insulation strip extruder mold

Guoyue also produces supporting molds and accepts mold customization.

Guoyue Molds fully meets market and customer demands.

The company independently designs and develops an automatic extrusion production line for nylon insulating strips, featuring high stability, high yield, and strong adaptability.

Extrusion molding (also called plasticizing extrusion) is a process where molten material in the mold is pressed out to form the final product with the desired shape.

The mold directly determines the shape and precise dimensions of the final product.

Insulating rubber strips, produced via molds with different cross-sections, are widely used in doors, windows, and curtain wall aluminum profiles.

FAQ

Q:How to start the project?

A: Send the drawings of the required products, we will provide the quotation (the quotation includes the number of cavity, the price, the appropriate model of extruder)

Q: as a new participant in polyamide extrusion, how do we learn to use this machine?

A: We can invite customers to visit our factories in China and train our factory for a week

Question: can we customize and purchase raw materials and molds?

A: We customize and supply PA66GF25 raw materials according to Chinese, European and American standards... Can also cut any shape of polyamide profile mold.

Please feel free to contact us if you have any questions.